Welded Wire Mesh Panels: The Building Blocks of Modern Infrastructure

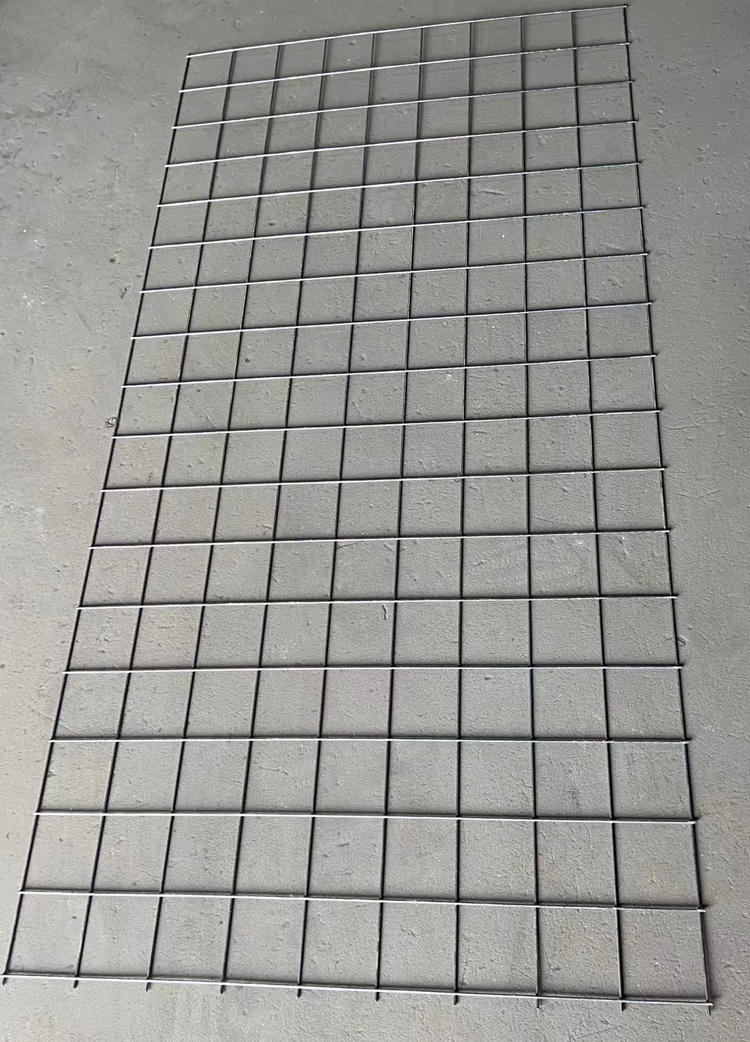

Welded wire mesh panels are flat, rigid sheets manufactured through the precise electric resistance welding of steel wires at their intersections. This process creates strong, uniform grids that are fundamental prefabricated components across countless industries. Unlike wire mesh in rolls, these pre-formed panels offer immediate structural integrity and ease of installation. They are primarily produced from low-carbon steel wire but are commonly finished with protective coatings like hot-dip galvanizing or PVC, or manufactured from stainless steel for specialized needs.

Defining Features and Core Advantages

The design and manufacturing process of welded mesh panels confer several critical benefits:

Exceptional Rigidity and Structural Integrity: The welded junctions create a fixed, non-flexing grid that acts as a unified load-bearing plane, resisting bending and shear forces.

Dimensional Stability and Consistency: Produced to exacting tolerances, they offer predictable strength and aperture sizes, which is vital for engineering and construction applications.

Ease of Handling and Installation: As ready-to-use components, they dramatically reduce on-site labor time. Panels can be quickly positioned, tied, clipped, or welded into place, streamlining project timelines.

Adaptability: Available in a vast array of standard and custom specifications, including wire gauge, mesh size (aperture), and overall panel dimensions (e.g., common construction sizes like 4.8m x 2.4m).

Durability: The choice of material and coating (e.g., thick galvanizing) ensures long-term resistance to corrosion, abrasion, and impact in demanding environments.

Primary Materials and Protective Finishes

Welded Wire Mesh (WWM) / Reinforcing Mesh: The basic black steel panel, often used as concrete reinforcement where it will be fully embedded.

Hot-Dip Galvanized Panels: The standard for durability. The panel is immersed in molten zinc after welding, providing a robust, sacrificial coating that resists rust in outdoor, industrial, and agricultural settings.

Stainless Steel Panels (304/316): Used where hygiene, chemical resistance, or maximum corrosion resistance is paramount (e.g., food processing, chemical plants, marine applications, architectural features).

PVC-Coated Panels: A steel wire mesh is coated with a fused layer of colored PVC. This provides excellent corrosion protection, improved aesthetics, and a safer, tactile surface, ideal for fencing, enclosures, and decorative partitions.

Key Applications of Welded Wire Mesh Panels

- Construction & Civil Engineering (The Largest Application)

Concrete Reinforcement (Welded Wire Fabric – WWF): Integrated into concrete slabs (floors, pavements, walls) to control shrinkage cracking, improve tensile strength, and distribute loads. Essential for modern slab-on-grade construction.

Permanent Formwork and Façade Support: Acts as a base for applying cladding materials or insulation systems in building envelopes.

- Industrial, Security & Storage Solutions

Machine Guards and Safety Barriers: Rigid panels used to create secure perimeters around hazardous machinery.

Security Fencing and Gates: Provides a strong, see-through barrier for factories, warehouses, and utilities.

Partitions, Mezzanine Decking, and Storage Rack Decking: Creates secure cages, reinforces shelving, and provides a solid, ventilated surface for storage systems.

- Agricultural and Animal Husbandry

Livestock Enclosures and Caging: For poultry, rabbits, and other animals, offering secure, ventilated, and durable confinement.

Agricultural Partitions and Sorting Pens.

- Infrastructure and Landscaping

Gabion Baskets: Modular, wire-framed boxes filled with stone, used for retaining walls, erosion control, and landscaping features.

Rockfall and Slope Stabilization Nets.

- Architectural and Decorative Uses

Decorative Screens and Balustrades: Used in modern architecture for sunshades, railing infills, and decorative interior or exterior features.

Planter Grates and Tree Guards.

Selection Guide for Optimal Performance

Choosing the correct panel requires careful consideration of:

Application Load: Determine the required strength (wire diameter and steel grade).

Environmental Conditions: Select the coating (galvanizing, PVC, stainless steel) based on exposure to moisture, chemicals, or weather.

Aperture Size: Dictates visibility, airflow, security level, and the size of materials it must contain or filter.

Panel Dimensions: Must align with the structural layout to minimize cutting and waste.

Conclusion

Welded wire mesh panels are far more than simple sheets of wire; they are high-performance, engineered building components. Their unique combination of strength, consistency, and versatility makes them indispensable in constructing safer, more durable, and more efficient structures—from the floors we walk on and the fences that secure our premises to the systems that support global industry and agriculture. As a prefabricated solution, they represent a cornerstone of modern, cost-effective, and reliable construction and manufacturing practices.

мэдин сетка

мэдин сетка